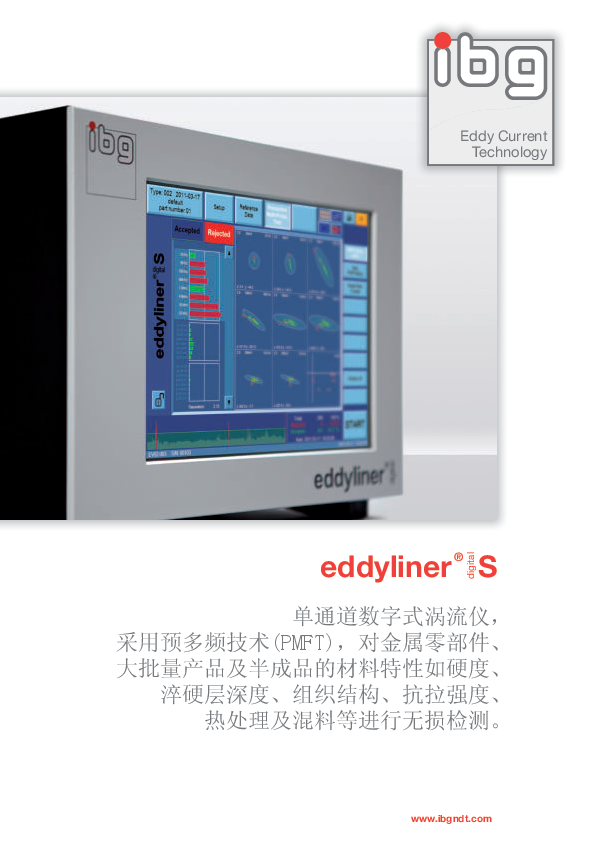

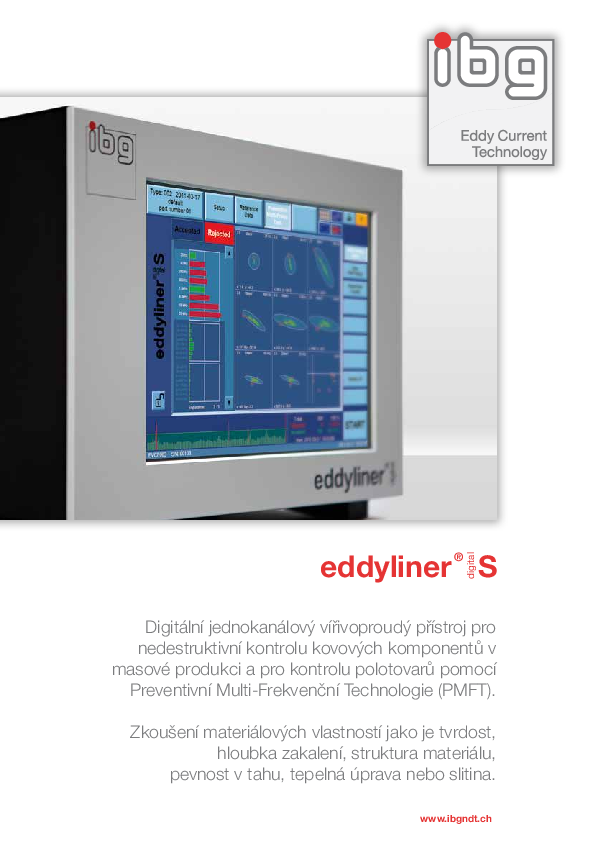

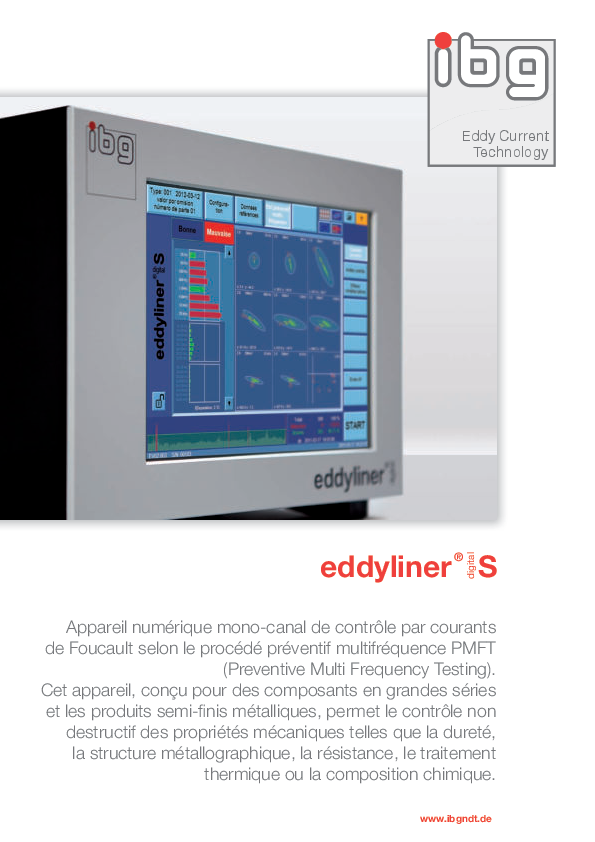

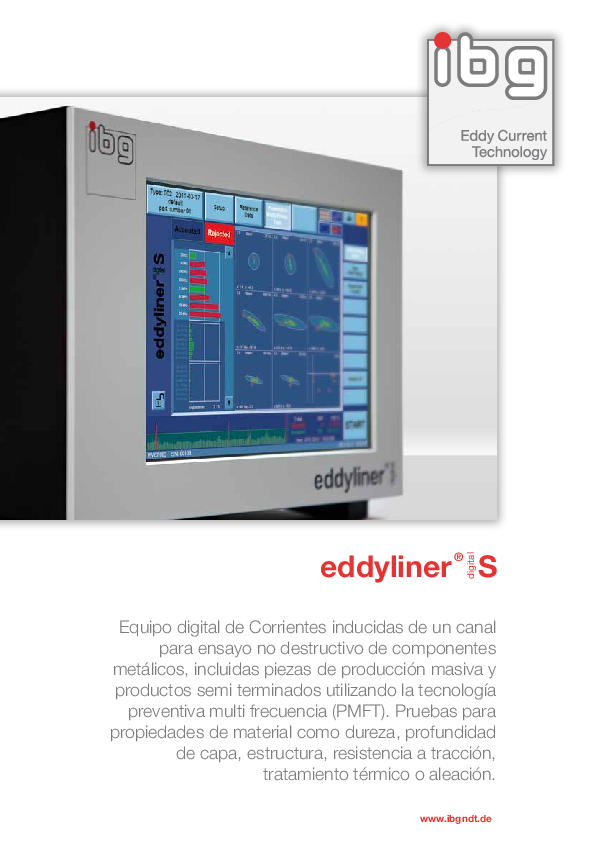

eddyliner S: Leading Eddy Current Testing for Production and Labs

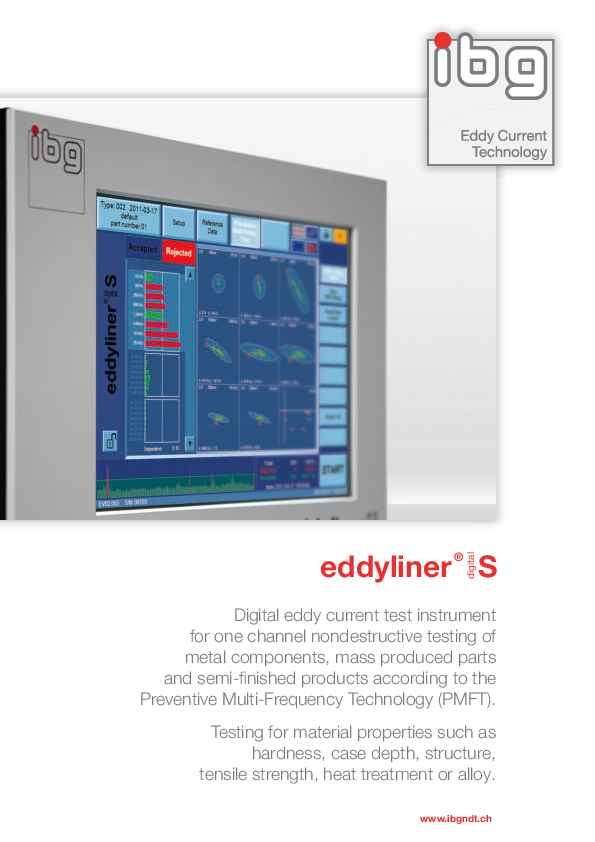

Digital eddy current test instrument for one-channel nondestructive testing of metal components, mass-produced parts, and semi-finished products according to the Preventive Multi-Frequency Technology (PMFT). Testing for material properties such as hardness, case depth, structure, tensile strength, heat treatment, or alloy.

eddyliner S: Reliable Eddy Current Testing with ibg Technology

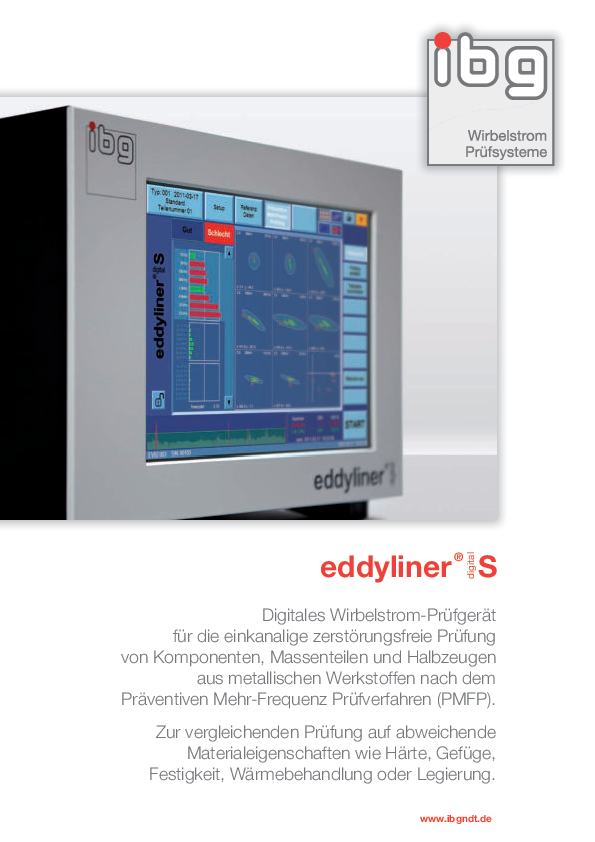

Compact Design and User-Friendly Interface for Seamless Eddy Current Testing

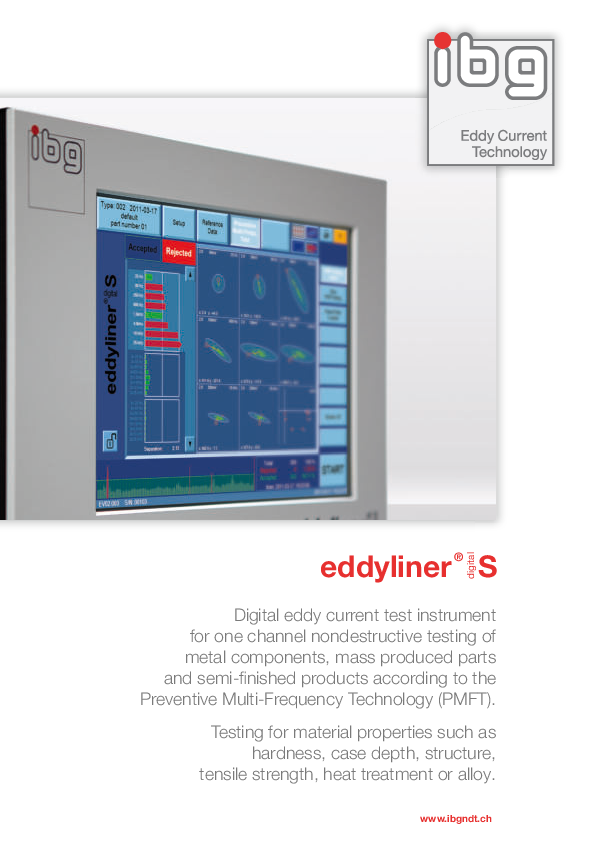

The eddyliner S distinguishes itself with a compact design for all one-channel structure applications with one coil at one part location combining that with the well-known ibg test reliability and ease of operation. The ergonomic interface facilitates intuitive and simple operation via touch screen. All functions and test results are captured at a glance. In NDT, fast and reliable calibration is key. ibg's "good part only" concept streamlines setup, while our eddyliner system integrates advanced tech for dependable testing.

Rapid and Reliable Eddy Current Testing Setup with ibg's Innovative Calibration Method

Calibration with ibg’s unique good part only concept enables setup within a few minutes true to the motto: “Do you still calibrate or are you already testing?” An adequate number of good parts is recorded as reference parts. From their eddy current signals tolerance zones are automatically generated encompassing the metallurgical magnetic fingerprint of the group of good parts for all PMFT test frequencies. After recording good parts, testing can be immediately started. Faster starting yet more reliable eddy current testing is not possible.

Seamless Integration and Advanced Technology for Reliable Eddy Current Testing

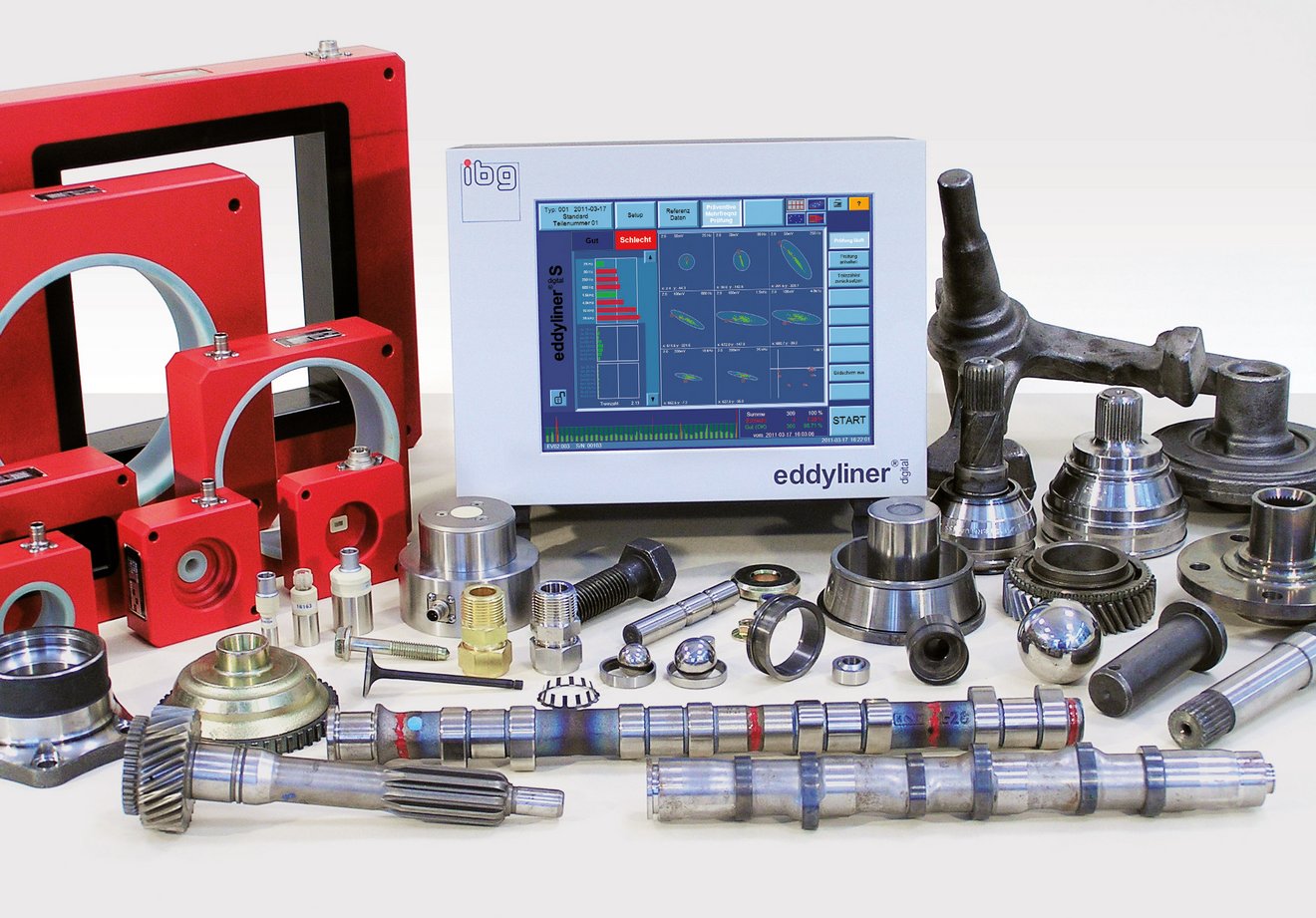

The eddyliner is based on the ibg system concept proven for decades. All coils and probes of the ibg system family can be used. The eddyliner is therefore recommended not only for the solution of new tasks but also as an upgrade for existing installations to be equipped with state-of-the-art eddy current technology.

Digital processing of the measuring signal with special processors immediately after the pre-amplifier guarantees highly stable, and test results.

Overview of Information about eddyliner S

Connections

| IO-ports | optically isolated interface for PLC connection with 32 inputs and 32 outputs |

| Network | Gigabit Ethernet |

| XVGA | PXVGA interface allows connection to a monitor or projector, an essential feature for training courses. |

| Printer | Commercially available printers may be connected via USB 2.0 or Ethernet to print out test results. |

| USB0 | Two USB ports on the back side for data storage. |

Technical Data

| Screen | Tough 10.2” TFT touch screen, color display, resolution 1,024 x 768 pixels, operable with gloves |

| Power supply | 100-240 V, 50/60 Hz |

| Protection class | IP41 (mounted) |

| Ambient temperature | 0 – 45°C |

| Relative humidity | max. 85%, non-condensing |

| Dimensions (WxHxD) | 304 x 229 x 200 mm |

| Weight | 6 kg |

Available for download:

Catalogues of our eddy current instruments

The catalogs are also available in other languages. Click here to go to the download center

Contact Us