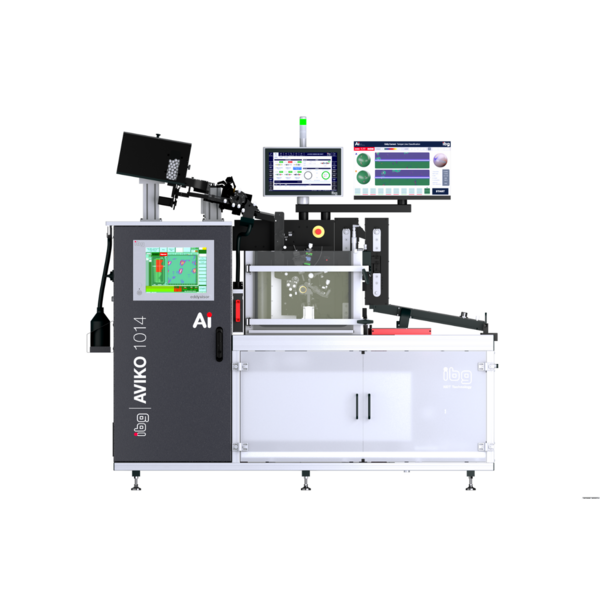

AVICO G3 WET Ceramic: Elevate Your Ball Inspection with AVIKO's Advanced Technology

Explore AVIKO's state-of-the-art high-speed ball inspection tech, evaluating surface and sub-surface quality at an impressive 34,000 pcs/hr. Custom probes match your ball's material, while optional accessories like elevators, conservation units, demagnetizers, and packaging machines elevate your inspection process. Achieve effortless integration for enhanced efficiency and precision with our comprehensive automation solutions.

Unlock Precision with AVIKO G3 WET Ceramic Ball Scanner

AVIKO WET ceramic ball scanner is one sided machine where the scanning is performed by an enhanced electro-optical probe, sub-surface eddy-current probe, and specially designed electro-vibration probe. All probes are evaluated by the eddyvisor evaluation unit and sorted based on AI evaluation.

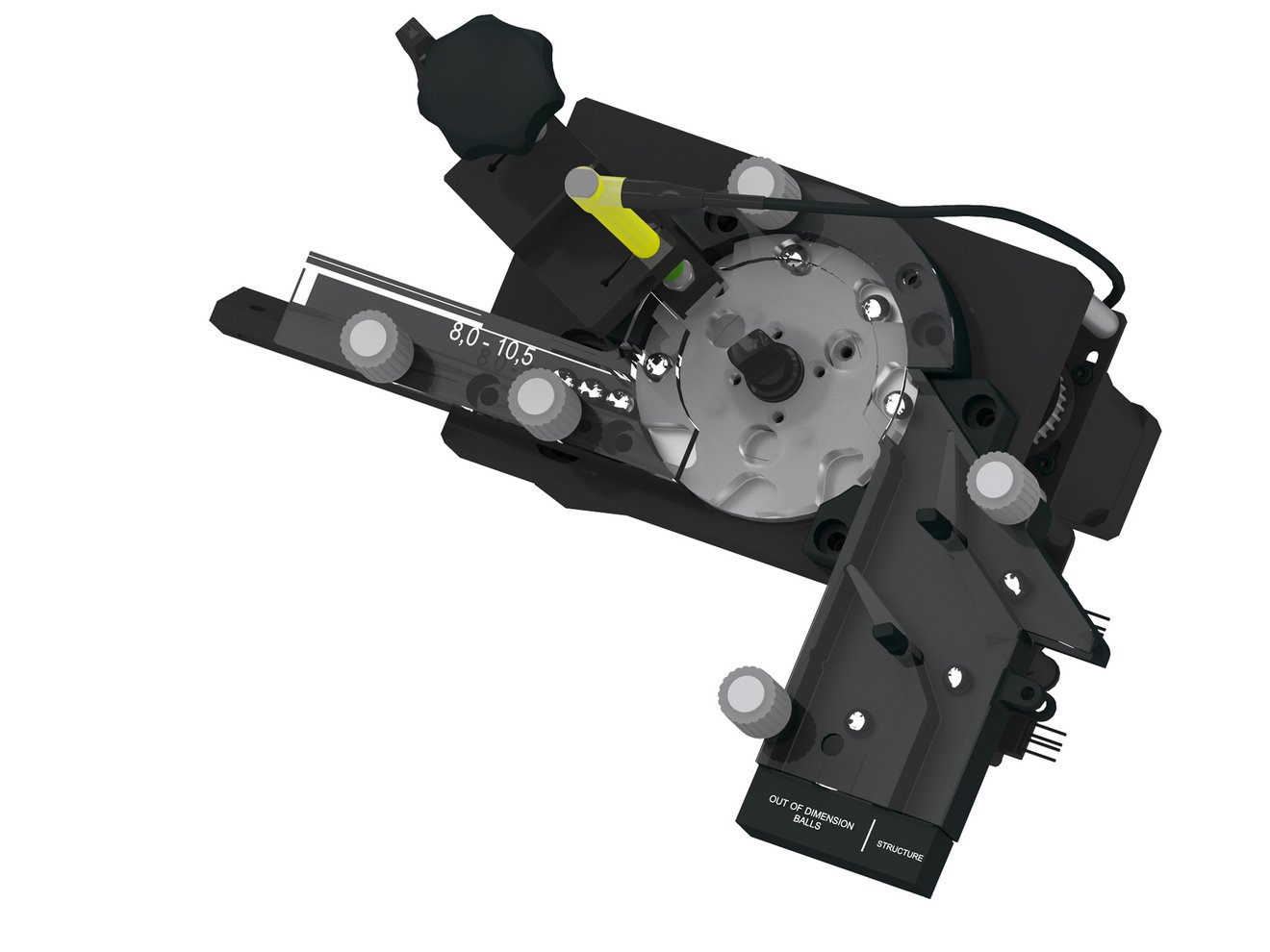

Enhance Precision: AVIKO G3 Machine Upgrade for More Accurate Diameter Validation

As a part of enhancing our latest AVIKO G3 machine series, we've introduced an advanced diameter validation solution that significantly improves precision. This technology can exclude balls deviating by ± 1 μm from the chosen ball diameter. This precise sorting happens before the monitoring point scan, reducing wear and tear caused by NOK balls.

Diameter Test

As part of the upgrade of our new generation AVIKO G3 machines we have implemented a brand new diameter validation solution which is much more precise with ability to exclude the balls which are ± 1 μm out of the selected ball diameter. The balls are rejected prior to the monitoring point scanning which prevents additional wear and tear of the machine parts with NOK balls.

Order Information

| Model | Sorting Diameter (mm) | Order Number |

|---|---|---|

| AVIKO 0610 G3 WET - CERAMIC | 5.556 - 10.319 | K 092 200C |

| AVIKO 1014 G3 WET - CERAMIC | 9.500 - 19.050 | K 092 400C |

| AVIKO 1419 G3 WET - CERAMIC | 13.494 - 19.050 | K 092 600C |

| AVIKO 1830 G3 WET - CERAMIC | 18.000 - 30.163 | K 092 800C |

Scan Speed

| Machine | Min. | Ball | Max. | Ball | Min. | Scan Speed | Max. | Scan Speed |

|---|---|---|---|---|---|---|---|---|

| [mm] | [inch] | [mm] | [inch] | Standard [pcs/hr] | Aerospace [pcs/hr] | Standard [pcs/hr] | Aerospace [pcs/hr] | |

| AVIKO 0610 G3 WET | 5.556 | 7/32 | 10.319 | 13/32 | 10 050 | 6 950 | 6 550 | 4 250 |

| AVIKO 1014 G3 WET | 9.525 | 3/8 | 14.600 | - | 7 100 | 6 150 | 4 200 | 3 300 |

| AVIKO 1419 G3 WET | 13.494 | 17/32 | 19.050 | 3/4 | 4 650 | 3 850 | 2 800 | 2 350 |

| AVIKO 1830 G3 WET | 18.000 | - | 30.163 | 1-3/16 | 2 800 | 2 150 | 1 250 | 1 000 |

| AVIKO G3 WET CERAMIC 0306 / 0610 / 1014 / 1419 / 1830 | |||

|---|---|---|---|

| Dimensions (L×W×H) | 2 030 × 700 × 1 850 (mm) | ||

| Weight | 410 kg | ||

| Sorting groups | 3 (OK, EOT probe rejection; EVT/ECT probe rejection) | ||

| Input Power (230V) | 230V, 50Hz/60Hz (Type E plug) | ||

| Input Power (110V) | 110V, 50Hz/60Hz (Type B plug) |

| SCAN AREA width | MAX. DEFECT size | |

|---|---|---|

| Electric optical probe | 1.2 mm | Spot defect Ø 600 μm |

| Electric vibration probe | - | Deep flat 300 μm |

| Eddy current probes | 2 mm | Metal inclusions |

Contact Us