Elevating Metal Component Inspection with Advanced Vibration Analysis

Vibration analysis is a sophisticated and invaluable non-destructive testing (NDT) technique employed in the evaluation of metal components across a diverse range of industries. This method capitalizes on the fundamental principles of mechanical vibrations to uncover structural anomalies, geometrical imperfections, defects, and weaknesses in metal parts. Through the precise measurement and analysis of vibrations, engineers and inspectors gain critical insights into the integrity and performance of these vital components.

Uncovering Metal Secrets: Vibration Analysis in Action

At its core, vibration analysis revolves around the response of a metal part to an applied force or mechanical excitation. When a force is introduced, whether through mechanical stress, impact, or resonance, the metal component undergoes vibrations. These vibrations propagate through the material and can reveal a wealth of information about its condition.

Unlocking Metal Insights: Vibration Analysis of Natural Frequencies

One of the primary techniques used in vibration analysis is the measurement of natural frequencies and mode shapes. Every metal component has unique natural frequencies at which it vibrates when subjected to an external force. These frequencies are determined by the component's geometry, material properties, and boundary conditions. By exciting the metal part with controlled vibrations and monitoring its response, engineers can identify deviations from expected natural frequencies, which may indicate the presence of defects or changes in material properties.

Beyond the Surface: Vibration Analysis Revealing Hidden Metal Defects

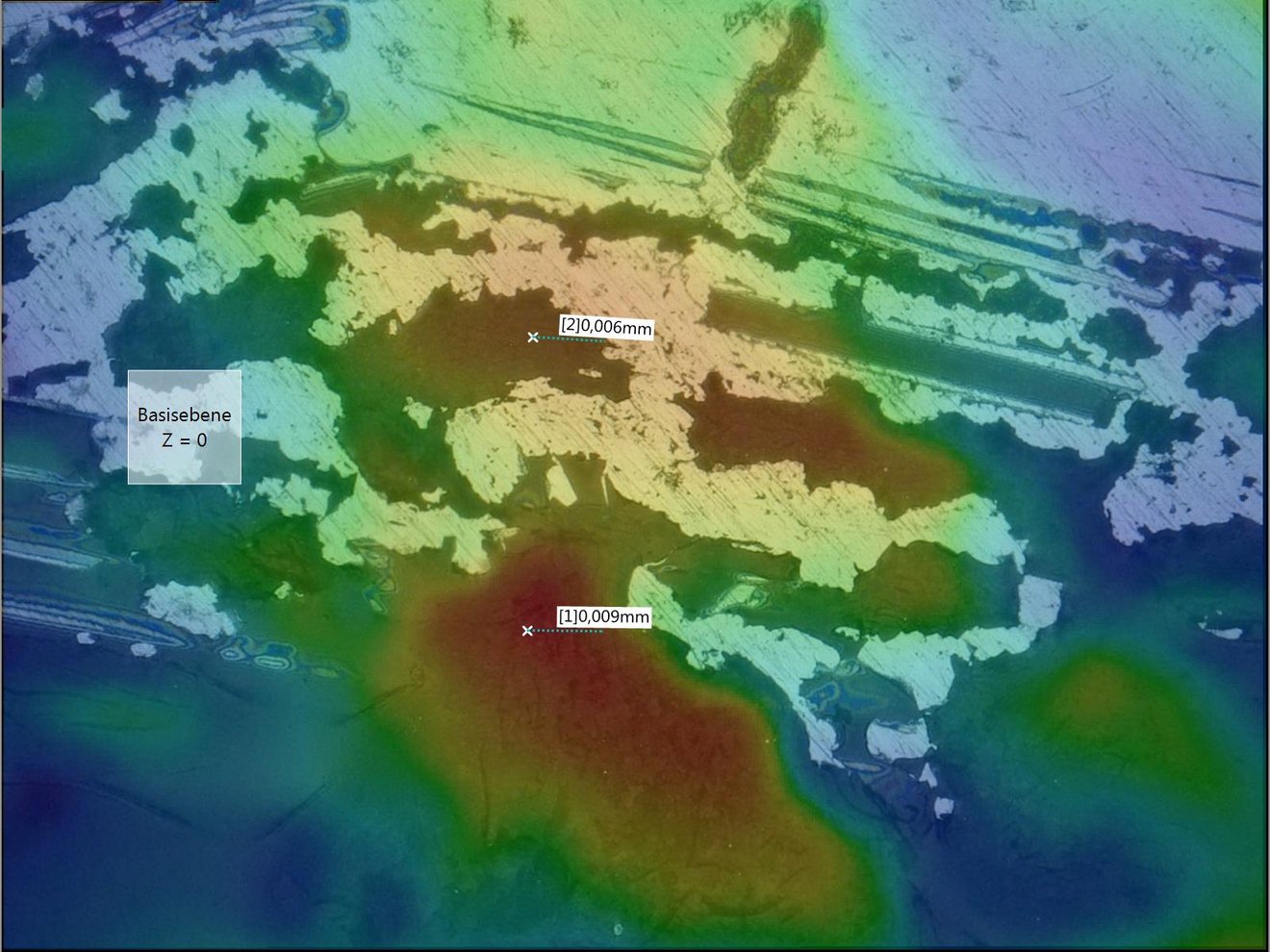

Moreover, vibration analysis can detect other critical issues, including cracks, fatigue, delamination, and material degradation. It is particularly adept at identifying hidden defects that may not be apparent through visual inspection alone.

Preserve Integrity: Non-Invasive Vibration Analysis for Metal Components

One of the standout advantages of vibration analysis is its non-invasive nature. It does not require the disassembly or alteration of the metal part being tested, preserving its structural integrity. This non-destructive character is particularly valuable when inspecting intricate or sensitive components.

Critical Role of Vibration Analysis Across Industries: Aerospace, Manufacturing, and Automotive

The applications of vibration analysis in metal parts testing are widespread. In the aerospace industry, it is pivotal in assessing the structural health of aircraft components such as wings, landing gear, and engine mounts. In manufacturing, it helps maintain the quality of machined parts, ensuring they meet precise specifications. In the automotive sector, vibration analysis aids in evaluating the performance and durability of critical components like engine parts and suspension systems.

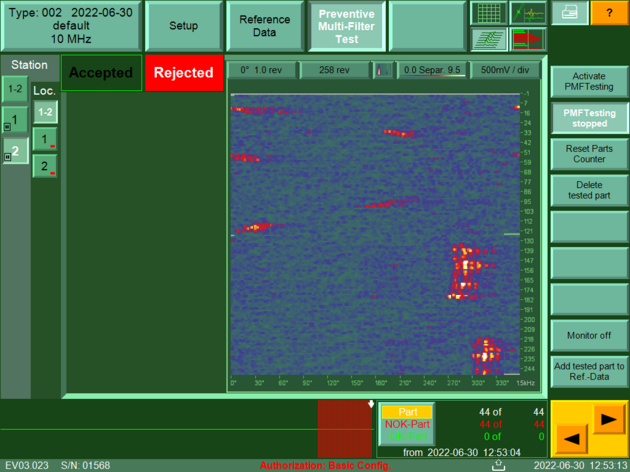

Advanced Vibration Analysis Technology: Precision Insights into Component Shape and Condition

Modern vibration analysis systems are equipped with advanced sensors and data acquisition technologies. These systems can capture and analyze complex vibration signals with high precision, providing detailed information about a component's surface and shape. Additionally, software tools can assist in the visualization and interpretation of vibration data, enabling engineers to make informed decisions.

Ensuring Metal Component Reliability: The Vital Role of Vibration Analysis

In summary, vibration analysis is an indispensable tool in the arsenal of non-destructive testing techniques for metal parts. By examining the response of metal components to mechanical excitation, it offers valuable insights into their structural integrity, performance, and potential defects. With ongoing advancements in sensor technology and data analysis, vibration analysis continues to play a pivotal role in ensuring the reliability and safety of metal parts in diverse industries.

Discover Precision and Reliability with ibg's State-of-the-Art Vibration Analysis Solutions

ibg's Vibration Analysis is a state-of-the-art solution designed to detect concealed defects within spherical objects. ibg’s technology for Vibration Analysis prioritizes precision in inspections, offering dependable results in the age of paramount quality control learn more about ibg's special systems as Vibration Analysis equipment here. Contact us today to discover how ibg's Vibration Analysis can elevate your quality control processes and secure the integrity of your spherical components. Trust ibg for results that matter.

Contact Us